Technology

Innovation and Versatility

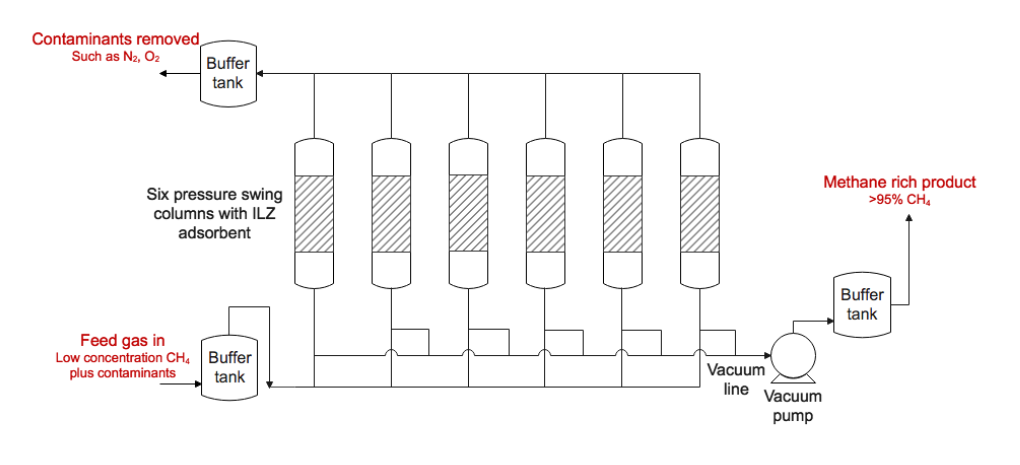

GCT’s system is simplified in this Process Flow Diagram.

The process consists of:

- Adsorption – methane is adsorbed by ILZ across six adsorption columns

- Regeneration – the columns are regenerated via depressurisation, blowdown, evacuation, and re-pressurisation. Gas flows are passed between beds using a novel approach to optimise methane recovery and energy efficiency

- Methane (and any CO2) are collected from the bottom of the columns and contaminants (e.g. N2, O2) from the top

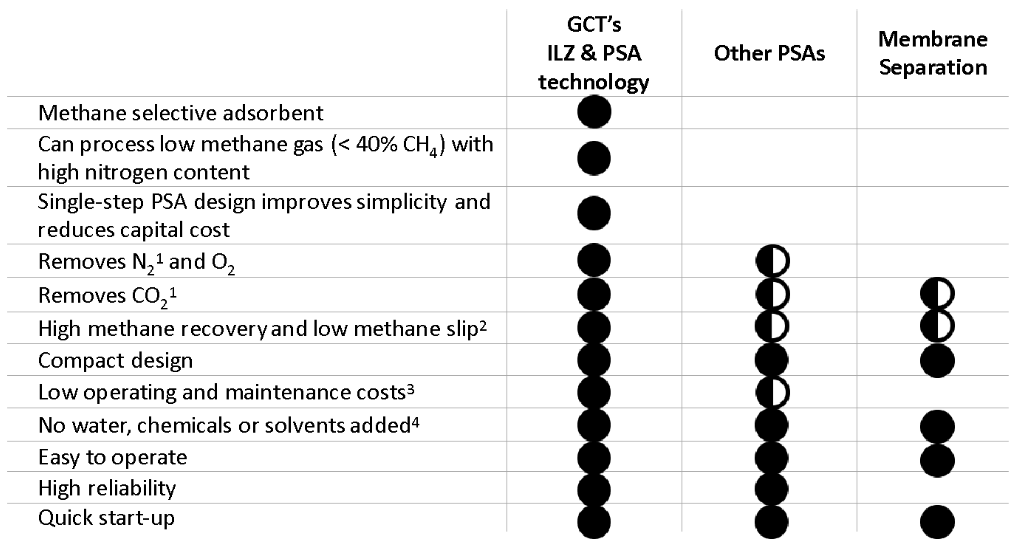

The technology delivers additional value and can be used for a wider range of scenarios than other gas separation technologies on the market.

Table notes:

- GCT’S technology removes N2 and CO2 better than other methods

- GCT’S technology provides better methane recovery than other methods

- GCT’s technology uses less adsorbent and less equipment than other methods

- Recycled water may be required to operate vacuum pumps if required by local legislation

Pilot Project

Proven at Pilot Scale

A methane upgrading system was successfully fabricated, installed, and operated in the Qinshui Basin in Shanxi province, China, in July 2020.

The system upgrades low concentration methane from a coal mine to a high concentration commercial stream.

The project was delivered in 3 months despite COVID-19 challenges, and it demonstrated the upscaling capability of GCT’s technology.

GCT have multiple patents covering their unique technologies

Patents

The US versions are:

US10562005B2 Method for Gas Separation (2015)

US10279305B2 Method for Gas Separation (2015)

US20170348670A1 Method for Gas Separation (2015)